| Page Properties | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||

|

iLab Name: LPKF Mill

iLab Kiosk: BRK Packaging and Assembly Core

FIC: Dimitrios Peroulis

Owner: Mihailo Bradash

Location: BRK 2254 - Galley

Maximum Wafer Size:

| Table of Content Zone | ||||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

|

Overview

General Description

Maximum material Size: 200 X 260 X 10mm

Maximum PCB Platable Size: 200 X 260 mm (for reference if through hole plating will be required)

Please Read this Before Requesting Training on this Tool

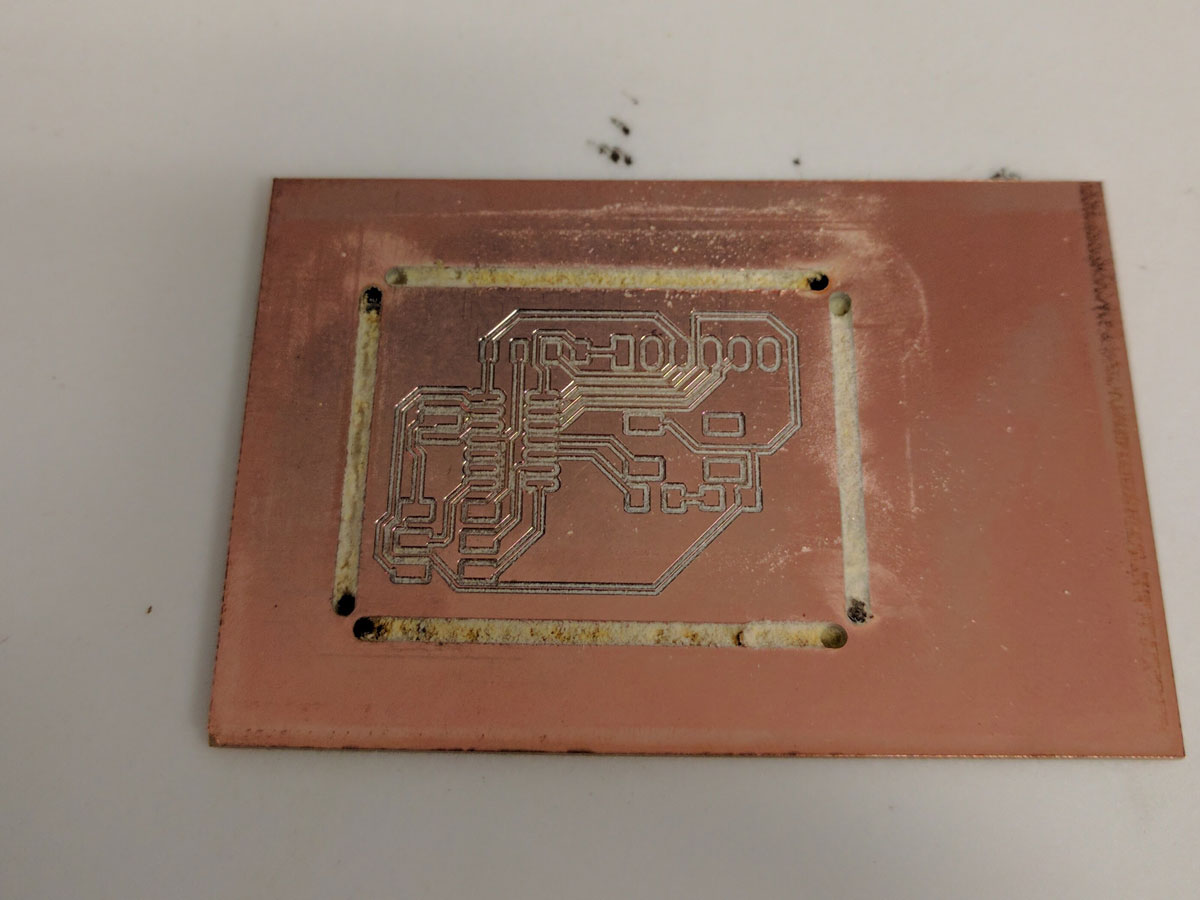

Notice 1:This tool produces bare copper boards and limited 3D milling. The image to the right is an example board produced by an | |||||||

Notice 2: Birckdoes not provide cutting tools to operate this tool. Before you can be trained on this tool, you will need Page 7 - Part Number 129103-1 - Starter Package - $450 (2020 pricing) See catalog link to the right for details and pricing options. |

| ||||||

Notice 3: Due to Prior issues with the LPKF mill, and extensive updates to the tool. Birck has decided to move this tool to a "selective approval" use case. The goal is to have that user on the tool frequently so they become, and maintain, proficiency at a level that will reduce potential damage to the tool due to operator errors. |

Ok, so I read that, and I don't think it's a good fit. Now what..?

| A simple google search for prototype PCB fabrication will turn up many options for online short run PCB services. Review their capabilities carefully as they do vary from service to service. Some offer same day turn around! |

Specifications

| Description | Value |

|---|---|

| Workplace noise level | ~71 dB (A), without soundproof hood and dust extraction |

| Range of spindle speeds | Up to 10,000 rpm (variable) |

| X and Y feed rate | 150 mm/s |

| Drilling rate | 150 strokes per minute |

| Tool Change | Manual |

| Tool shank | 3.175 mm diameter (0.125 in) |

| Cutting depth adjustment | Automatic |

| Working area | 305 x 229 x 23 mm |

| Resolution(X/Y) | +/- 0.25 um (0.01 mil) |

| Repeatability | +/- 5 um (0.2 mil) |

| Minimum drill diameter | 0.2 mm |

Technology Overview

Sample Requirements and Preparation

Items that require milling should be prepared as either a Gerber, DWG/DXF, or G-Code IPT/SLDPRT file type.

Depending on your file type preparation for milling will be different, please see the appropriate sub sections within the "Standard Operating Procedure" section.

Standard Operating Procedure

System start up

- Start the PC.

- Check that the switch on the dust extraction unit is set to the manual position.

Gerber files

| Expand |

|---|

DWG/DXF files

| Expand |

|---|

IPT/SLDPRT files

| Expand |

|---|

Questions & Troubleshooting

Process Library