| Page Properties | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||

|

iLab Name: LPKF Mill

iLab Kiosk: BRK Packaging and Assembly Core

FIC: Dimitrios Peroulis

Owner: Mihailo Bradash

Location: BRK 2254 - Galley

Maximum Wafer Size:

| Table of Content Zone | ||||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

|

Overview

General Description

Maximum PCB Overall material Size: 230 X 330 mm200 X 260 X 10mm

Maximum PCB Platable Size: 200 X 260 mm (for reference if through hole plating will be required)

Please Read this Before Requesting Training on this Tool

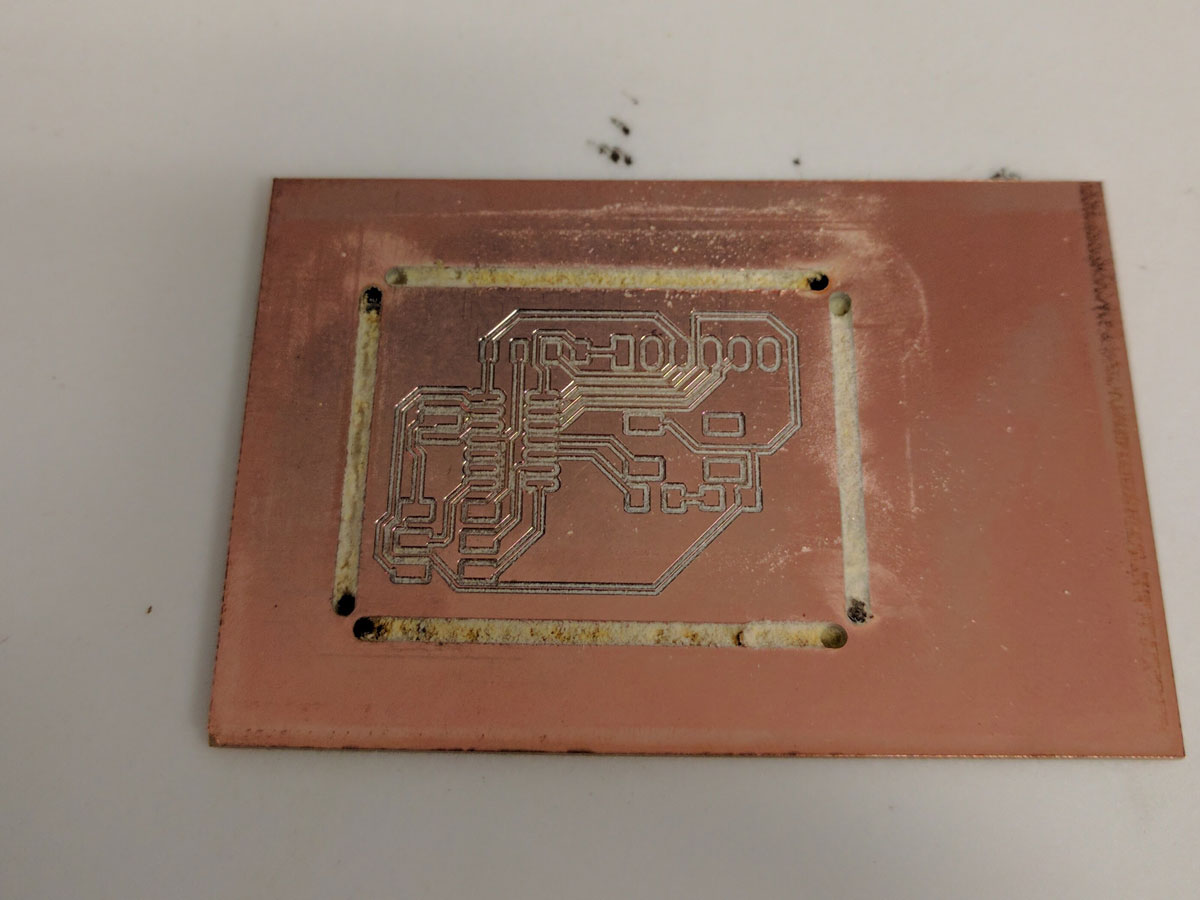

Notice 1:This tool produces bare copper boards onlyand limited 3D milling. The image to the right is an example board produced by an | |||||||

Notice 2: Birckdoes not provide cutting tools to operate this tool. Before you can be trained on this tool, you will need Page 7 - Part Number 129103-1 - Starter Package - $450 (2020 pricing) See catalog link to the right for details and pricing options. All tool bits must be ordered with the distance rings. |

| ||||||

Notice 3: Due to ongoingPrior issues with the LPKF mill, and extensive updates to the tool. Birck has decided to move this tool to a " Super Userselective approval" format of use case. means each professor/group should select one student to be the user for the entire group and all fabrications at the tool should be completed by that user or a BNC Engineer. The goal is to have that user on the tool frequently so they become, and maintain, proficiency at a level that will reduce potential damage to the tool due to operator errors. |

Ok, so I read that, and I don't think it's a good fit. Now what..?

| A simple google search for prototype PCB fabrication will turn up many options for online short run PCB services. Review their capabilities carefully as they do vary from service to service. Some offer same day turn around! |

Ok, so you still want to use the LPKF. Please continue below for more information!

Specifications

| Description | Value | ||

|---|---|---|---|

| Workplace noise level | 71 ~71 dB (A), without soundproof hood and dust extraction | ||

| Range of spindle speeds | Up to 10010,000 rpm (variable) | ||

| X and Y feed rate | 150 mm/s | ||

| Drilling rate | 150 strokes per minute | ||

| Tool Change | AutomaticManual | ||

| Tool Magazine | Up to 15 positions | Tool shank | 3.175 mm diameter (0.125 in) |

| Cutting depth adjustment | Automatic | ||

| Working area | 305 x 229 x 23 mm | ||

| Resolution(X/Y) | +/- 0.25 um (0.01 mil) | ||

| Repeatability | +/- 5 um (0.2 mil) | ||

| Minimum drill diameter | 0.2 mm |

Technology Overview

The modified LPKF milling machine now makes use of a "Duet 3" 3D printer control board and it's respective interface. This along with a revamped z-drive and spindle motor allow for the use of true 3D milling operations as compared to the prior 2D.

Sample Requirements and Preparation

Items that require milling should be prepared as either a Gerber, or IPT/SLDPRT (3D CAD) file type.

Depending on your file type preparation for milling will be different, please see the appropriate sub sections within the "Standard Operating Procedure" section.

Standard Operating Procedure

System start up

- Enable the tool in iLabs and make sure tool has started up

- Start the and power is switched on.

- Turn on and log-in to the machines PC.

- Check that the switch on the dust extraction unit is set to the automatic manual position.

- Set the desired extraction power (75-100% depending on size of board)

- Open the cover of the Protomat S103 and set the main switch to the ON position.

- Close the cover.

- Start the CircuitPro software on the PC. A series of initialization steps will take place automatically. Once these complete, the Protomat S103 is ready to use.

- It is possible that the mill/drill head is equipped with a tool, used by a production process in the past, and mill cannot identify the current state during initialization. When CircuitPro is checking the tool status two things may occur:

- Tool status is known - the tool will be placed into the corresponding position of the tool magazine.

- Tool status is unknown - you will be prompted to select which tool is currently in the spindle (1-15, or none). Click OK.

- It is possible that the mill/drill head is equipped with a tool, used by a production process in the past, and mill cannot identify the current state during initialization. When CircuitPro is checking the tool status two things may occur:

Processing Gerber Files utilizing Circuit Pro

- Open CircuitPro template. File > New > select the appropriate template for your project.

- Press the import icon, or alternativley, File > Import.

- Hold down Ctrl while selecting all required layers for your project > click Open

- Change the "Layer/Template" column for each row, to map the data to the appropriate layer within CircuitPro. > press OK

- More about Gerber File Format and ODB++ File Format.

- Check settings on layers to make sure they are correct

- If NC drill layer is improperly displayed you may need to change the N digit from 4 to 3. This setting signifies how many zeros the software uses. The setting is normally either 2:4 or 2:3

- Click on the layer and review the overall dimensions for correctness. You may need to change from English units to metric depending on export options in the design software.

- Press OK and your design should be displayed on screen.

Board Production in Circuit Pro

System Shutdown

- Save the current CBF file

- Exit CircuitPro Software by clicking File > Exit.

- Open the cover of the Protomat S103 and set the main switch to the OFF position.

- Log off the PC.

Questions & Troubleshooting

Process Library

- From the desktop screen select and open the "LPKF" hyperlink.

- From here you should be within the "Duet Web Controller" on the main "Dashboard" page, and ready to initialize the machine.

- To initialize the machine navigate to the "Home All" button and select, note make sure there is nothing preventing movement of the axis on the machine as this can result in a crash.

- Once machine has been homed navigate to the "Upload and Start" button at the top of the screen, and select.

- Upload your file as detailed by the file types below. If you have any issues with this step and or any following, please stop the machine and contact The responsible engineer for this tool.

Gerber files

| Expand |

|---|

Gerber files will use a program called "Flat CAM" to prepare machining paths. |

3D CAD files

| Expand |

|---|

3D CAD files either from Solidworks or Inventor can be used |