Solvents

Overview

Solvents are classified into polar and nonpolar categories depending on their chemical polarity. Polar solvents are further divided into polar aprotic and polar protic based on the ability to form hydrogen bonds.

Nonpolar Solvents

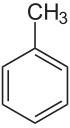

Toluene

Toluene is a nonpolar solvent used for degreasing. It is the first step in the standard 3 step TAI solvent clean.

Chlorobenzene

Chlorobenzene is a nonpolar solvent mainly used to obtain a undercut resist profile in positive photoresist. It is soluble in most organic solvents and insoluble in water. It considered to have "low to moderate" toxicity, and Toluene is suggested as a substitute for use as both as a degreasing solvent and resist undercut.

Polar Aprotic Solvents

Remover PG

Remover PG is a powerful polar aprotic solvent used for stripping photoresist.

- 99% N-Methyl-2-pyrrolidone (NMP), <1% added propritary surfactant

Miscible in water and most organic solvents

May be used to remove PMMA, Su-8, AZ1518 and AZ9260

- Can be used at room temperature (RT), or at elevated (50-80 C) temperatures for faster removal.

- Compatible materials include glass, ceramic, HDPE, PTFE (Teflon), and stainless steel

- Incompatible materials include Viton A and polyester

Manufacturer recommended process:

A two bath process is recommended by the manufacturer to reduce the chance of resist redeposition:

| Step | Temp. | Chemical |

|---|---|---|

| Soak #1 | RT, or 50-80 C | Remover PG |

| Soak #2 | RT, or 50-80 C | Remover PG |

| Soak #3 | RT | Isopropanol (IPA) |

| Rinse | RT | Water |

Manufacturer Info Sheet: Remover PG

PRS-2000

PRS-2000 is a N-Methyl-2-pyrrolidone (NMP) based solvent blend for removal of bulk positive PR and PR residual.

- Water soluble

- Designed to remove resist in ~1-20 minutes

- Compatible materials include 304 & 316 stainless steel, glass/quartz, Teflon (PTFE/PFA), PP, PE, Chemraz, Kalrez, Teflon

Metal attack:

Note PRS-2000 will etch some metals and substrates, etch rates (A/s) at 85 C:

| Al | Cr | Mo | Ti | W | ITO | TEOS |

|---|---|---|---|---|---|---|

| <0.5 | <1 | <1 | <0.4 | 0.4 | <1 | <1 |

Manufacturer supplied example of Mo and Al attack after 30 min at 75 C:

Manufacturer recommended process:

| Step | Temp. | Chemical |

|---|---|---|

| Bath | 65 - 85 C for 1 - 20 min. | PRS-2000 |

| Bath/Rinse | RT | Water |

| Dry | RT | N2 Dry |

Composition: (Estimate from MSDS)

- ~45% N-Methyl-2-pyrrolidone (NMP), a polar aprotic solvent.

- ~25% Sulfolane, a polar aprotic solvent with good solubility in hydrocarbons.

- ~12.5% 2-(2-Ethoxyethoxy)ethanol, a hygroscopic solvent.

- ~7.5% Monoisopropanolamine, a solvent for oils and fats.

- ~5% Triethylene glycol, a hygroscopic solvent and disenfectant.

- And water as the remainder of the solution.

Manufacturer Info Sheet: PRS-2000